Process 3 foods fall into two categories: foods that are mass produced in preparation for the next day’s business and foods that are cooked using Process 2 but are never served and thus end up back in cold holding.Ĭooking. Even though these foods pass through a cooking “kill step” more than once, the danger of “spore forming bacteria” (bacteria that leave behind spores that can survive the kill step and start reproducing again) presents a particular danger in this process because so much time passes between the time the food is first cooked and the time it is served to the customer. These foods pass through the danger zone (see Step 3 for more information) more than once before they are served to the customer and therefore must have their temperature strictly monitored in order to prevent contamination. Process 3: Complex food preparation (example: receive – store – prepare – cook – cool – reheat – hot hold – serve). Please note that some types of seafood require additional CCP’s like cold holding and receiving certification because of the risk of the buildup of bacteria-related toxins that are not removed by the cooking “kill step.” Consult with your local Board of Health for more information. After this food is cooked, it should be held hot until served or served in a specified amount of time before disposal to prevent contamination. See Step 3: Critical Limits for more information. For example, hamburger should be cooked at 155 degrees Fahrenheit for 15 seconds, while chicken should be cooked at 165 degrees Fahrenheit for 15 seconds. Depending on the type of food, it must be cooked to a specific temperature for a specified amount of time. Some examples: hamburgers, steak, various fish species.Ĭooking. This process involves cooking food before it is served, which means it takes one trip through the danger zone (see Step 3 for more information), and potential biological hazards are exposed to a kill step before the food is served. Process 2: Same day service (example: receive – store – prepare – cook – hold – serve). The above CCPs are specific to these Process 1 foods and therefore require that you set specific Critical Limits for each risk factor (see Step 3 for more information). Those more general factors should be addressed in the SOPs of your Prerequisite Program. It’s important to note that several other risks and hazards apply to Process 1 foods, like proper employee hygiene, properly sanitized food preparation equipment and utensils, etc. Some types of food in this category, especially sushi, ceviche, and shashimi, require freezing to kill potential parasites. A system must be in place to dispose of product that has sat unused too long.įreezing. Even if these foods are stored at the proper temperature, as time passes the risk of contamination grows. While the product is stored or after it has been prepared and is waiting to be served, it must remain below the 41 degree threshold to limit bacterial growth.ĭate marking. Many types of food in this category, especially shellfish, must arrive with a tag certifying its freshness, and the tag must be retained as proof.Ĭold holding. These foods must arrive below 41 degrees Fahrenheit. Some examples of Process 1 foods: oysters, salads, fresh vegetables, sushi, ceviche, shashimi. That means this food never goes through a “kill step” before it is served to customers, meaning the process of cooking the food, which kills most biological hazards, never occurs.

This food is served cold and is never cooked. Process 1: No cook step (example: receive – store – prepare – hold – serve). There are a few exceptions, but in general most menu items can be divided into three groups (please keep in mind that the CCPs listed below are the most common examples only actual CCPs may vary depending on the situation):

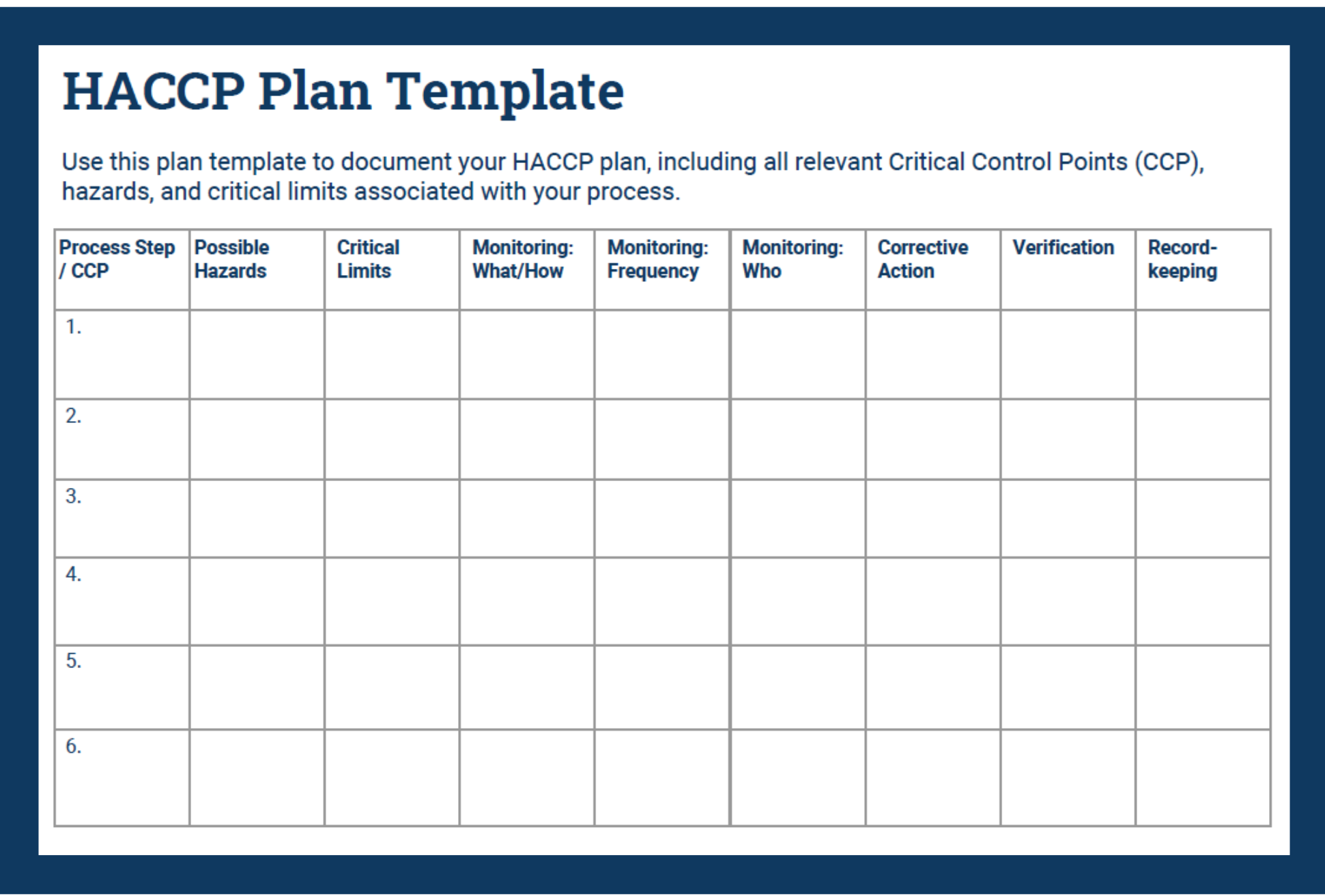

So how do you decide which points are a CCP and which can be handled by a Prerequisite Program? A good strategy is to analyze the food preparation process for each item on your menu. As we discussed in the last HACCP post, you need to organize the hazards and critical control points at every step in the food preparation process.

0 kommentar(er)

0 kommentar(er)